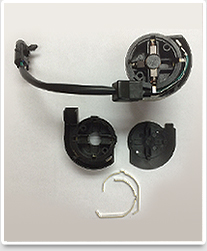

(Click on thumbnail to enlarge)

From initial concept and design to full production runs, at Legacy Plastics, Inc. we are proud to be a one-stop shop for custom molding jobs for many different industries. We were contacted by a client in the automotive industry to manufacture custom molds for brush housings and industrial plugs. Our facility maintains a variety of cutting edge injection molding machines, and we utilized them to fabricate these products from various engineering grade resins. The plug was a particularly complex project, involving over-molding 6 terminals in a 6 slide mold. The plug is used for an emergency power generator. We used our client’s specifications to create a 2D CAD drawing, and molded these various-sized parts to tolerances of ± 0.002″. To ensure that the work was of the highest quality, we visually inspected and fit each part to gage. Our quality work met our clients’ specifications and expectations, and we now manufacture 35,000 to 45,000 of these units to ship weekly based on our customer’s product releases.

To find out more about this custom molding project, please take a look at the following table or contact us directly.

CUSTOM MOLDS FOR BRUSH HOUSINGS & INDUSTRIAL PLUGS PROJECT HIGHLIGHTS

| Product Description | Metal Inserts in Custom Molds |

|---|---|

| Capabilities Applied/Processes | Primary:

|

| Equipment Used to Manufacture Part | Injection molding machines of various sizes, insert molding. |

| Overall Part Dimensions | 2" X 6" Varies |

| Tightest Tolerances | +/-.002 |

| Material Used | Various Engineering grade resins. |

| Material Finish | Matte & Smooth |

| In process testing/inspection performed | Visual and fit to gage |

| Industry for Use | Automotive |

| Volume | 35,000-45,000 units |

| Delivery/Turnaround Time | Ships on Weekly bases per customer releases |

| Delivery Location | Ships to Warner Electric |

| Standards Met | Customer Specifications, 2D CAD Drawing |

| Product Name | Brush Housings, Industrial Plugs |