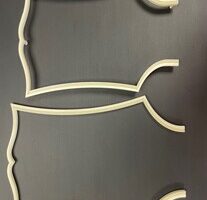

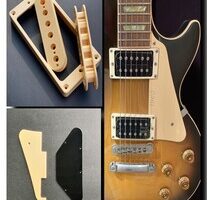

At our state-of-the-art facility, we utilize world class production techniques to provide efficient, high quality custom molding at competitive prices. Our team of experts at Legacy Plastics, Inc. utilizes highly precise equipment for jobs that range from industrial applications to providing custom, high gloss finishes for parts that require dazzling cosmetic appearance. A customer in the music industry contacted us to manufacture custom injection molded guitar parts. Cosmetic appearance was highly important for these components. Using a number of our precision injection molding machines, we fabricated guitar parts that included mounting rings, back plates, pick guards, coil forms, and truss rod covers. Each of these parts was constructed with high gloss and mirror finishes to our customers’ exact specifications. These guitar parts were molded to tolerances of ± 0.005″, with each one visually inspected to ensure the quality of construction and finish. We now manufacture over 1,000,000 of these parts annually for this client, shipping them out every week to many divisions.

(Click on thumbnail to enlarge)

For more information about this custom molding project, please take a look at the following table or contact us directly.

CUSTOM MOLDING OF GUITAR PARTS PROJECT HIGHLIGHTS

| Product Description | Custom die-cut mold and injection mold parts for guitar parts |

|---|---|

| Capabilities Applied/Processes | Primary:

|

| Equipment Used to Manufacture Part | Various inject molding machines |

| Overall Part Dimensions | Varies |

| Tightest Tolerances | +/-.002 |

| Material Used | ABS |

| Material Finish | High Gloss, Mirror finish |

| In process testing/inspection performed | Visual |

| Industry for Use | Music |

| Volume | + 1,000,000 annually |

| Delivery/Turnaround Time | Weekly shipments |

| Delivery Location | Varies |

| Standards Met | Customer Specifications, 2D CAD Drawing |

| Product Name | Mounting Rings, Back Plates, Pick Guards, Coilforms, Truss Rod Covers, |