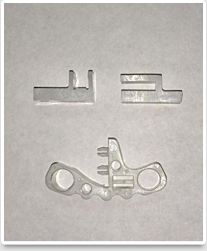

(Click on thumbnail to enlarge)

At Legacy Plastics, Inc., we have over 64 years of experience in providing consistent, high quality molding from our ISO 9001 compliant facility. We take pride in our ability to handle the most complex and intricate projects. This was exemplified when a client in the cellular industry contacted us to fabricate custom molds for cellular tower insulators. Using our customer’s specifications, our engineering department developed a 2D CAD drawing. We then utilized our state-of-the-art injection molding machine with a pick and place sprue picker. Acetal was used to create these precision components, which measured .200″ x .750″ when completed. Each part was molded to close tolerances of ± 0.002″, and was inspected visually to ensure the highest quality. This complex, multi-cavity mold is now used in high volume production runs. We manufacture 750,000 to 1,000,000 of these parts per year, shipped out monthly as requested by our client.

For further information on this project, please see the following table or contact us directly.

CUSTOM MOLDING FOR THE CELLULAR INDUSTRY PROJECT HIGHLIGHTS

| Product Description | Custom Molds for Cellular tower Parts |

|---|---|

| Capabilities Applied/Processes | Primary:

|

| Equipment Used to Manufacture Part | Injection molding machine, with pick & place sprue picker |

| Overall Part Dimensions | .200 X .750 |

| Tightest Tolerances | +/-.002 |

| Material Used | Acetal |

| Material Finish | Smooth |

| In process testing/inspection performed | Visual |

| Industry for Use | Cellular |

| Volume | 750,000 - 1,000,000 annually |

| Delivery/Turnaround Time | Shipped monthly as customer request |

| Delivery Location | Varies |

| Standards Met | Customer Specifications, 2D CAD Drawing |

| Product Name | Insulators |